English (pdf) Spanish (pdf) German (pdf)

When length matters.

Labor-saving technology is created so that a process can be completed with minimal human assistance. Its most significant advantages in the industry are faster production and lower labor costs. Besides these two very obvious benefits, it also replaces or reduces hard, physical or monotonous work. Certainly, the same rules apply when it comes to sausage production, especially on a major scale.

Keep or reduce?

One way to become more efficient is to reduce manpower while keeping the output stable. Another is to increase the output while keeping the same labor. The following example, taken from field experience, is the result of wonderful teamwork between ViskoTeepak and a customer. It clearly shows how the output can be increased without incurring extra labor costs.

Fibrous, size 102, 120 m/strand

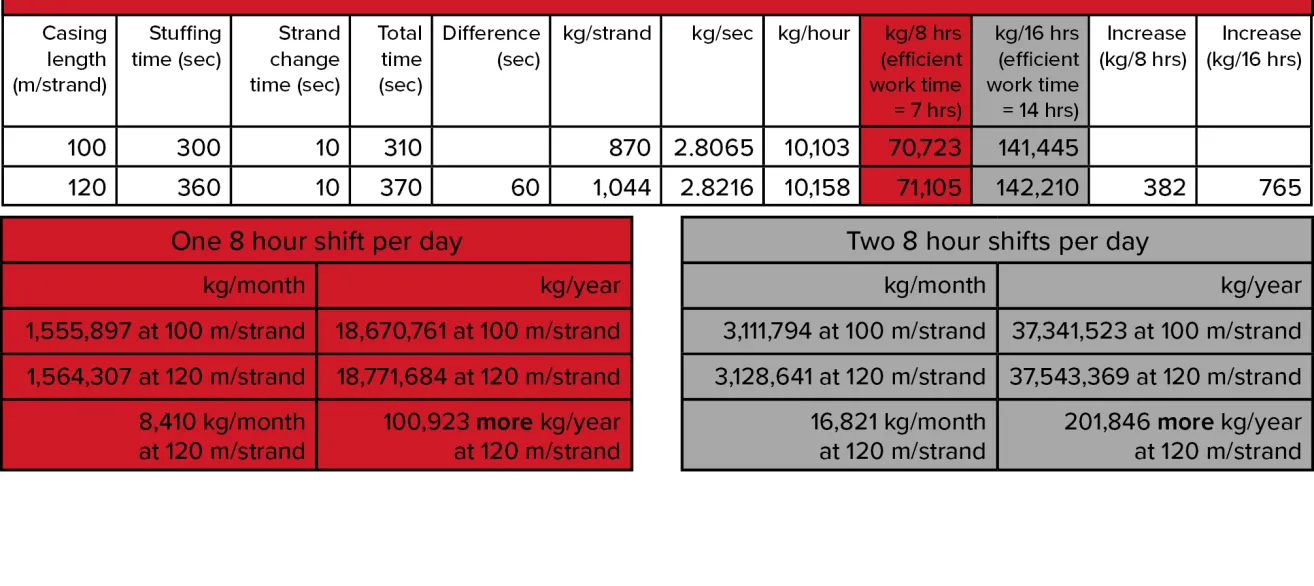

We made it possible for the customer to produce approximately 2,000 kg of sausages more per day. The method used was simply to increase the length of shirred fibrous casing per strand from 100 to 120 meters. By doing that the customer didn’t have to additionally invest in human resources or equipment. Moreover, the customer gained added value because the strands could be loaded less frequently, resulting in less casing waste during loading.

Calculation example

To visualize this and provide a better understanding of the achievement in terms of output, we did some math (see example below). For specific earnings or savings, please, contact your ViskoTeepak representative.