English (pdf) German (pdf) Spanish (pdf)

A new generation of peeling solution

RPD is a next-generation peeling solution that effectively facilitates casing removal during skinless frank production. It provides end users with an extremely efficient way of peeling sausages in multiple applications regardless of the type of emulsion used (pork, beef, chicken, and MDM) or even in vegetarian and vegan applications that have always been critical and challenging for peeling until now, when it becomes as easy as it gets.

What is dry peeling?

Dry peeling occurs when a casing is removed from sausages without moisturizing them by showering or water bath. The trolley with sausages is transported from the fridge directly to the peeling area for immediate processing. In some applications, even steaming could be reduced or entirely skipped.

What are the benefits?

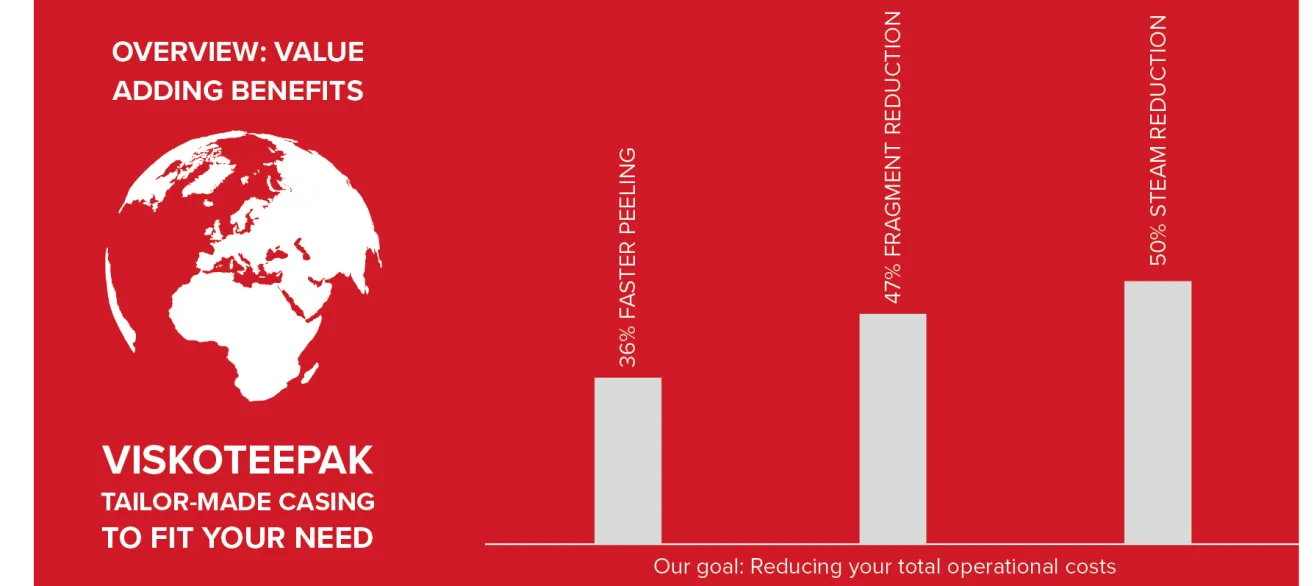

- Production-cost reduction – by reducing showering and steaming

- Time reduction – dry peeling can be done 3-4 hours after cooking and cooling

- Safety – less water used equals lower contamination risk

- Quieter, easier peeling

- Faster peeling

- Fragmentation reduction at peeler in dry and hard-to-peel applications