To read the whole article, please click on one of the links below.

English (pdf) Spanish (pdf) German (pdf)

At ViskoTeepak, we’re dedicated to pioneering excellence in food packaging. Through our commitment to innovation, we’ve transformed fibrous shirring technology, enhancing product quality and efficiency. Our recent adoption of spiral shirring and development of aziridine-free printing inks reflect our ongoing efforts to exceed industry standards. Join us as we explore our journey in advancing fibrous shirring and ink innovation, shaping the future of food packaging.

Transforming shirring technology

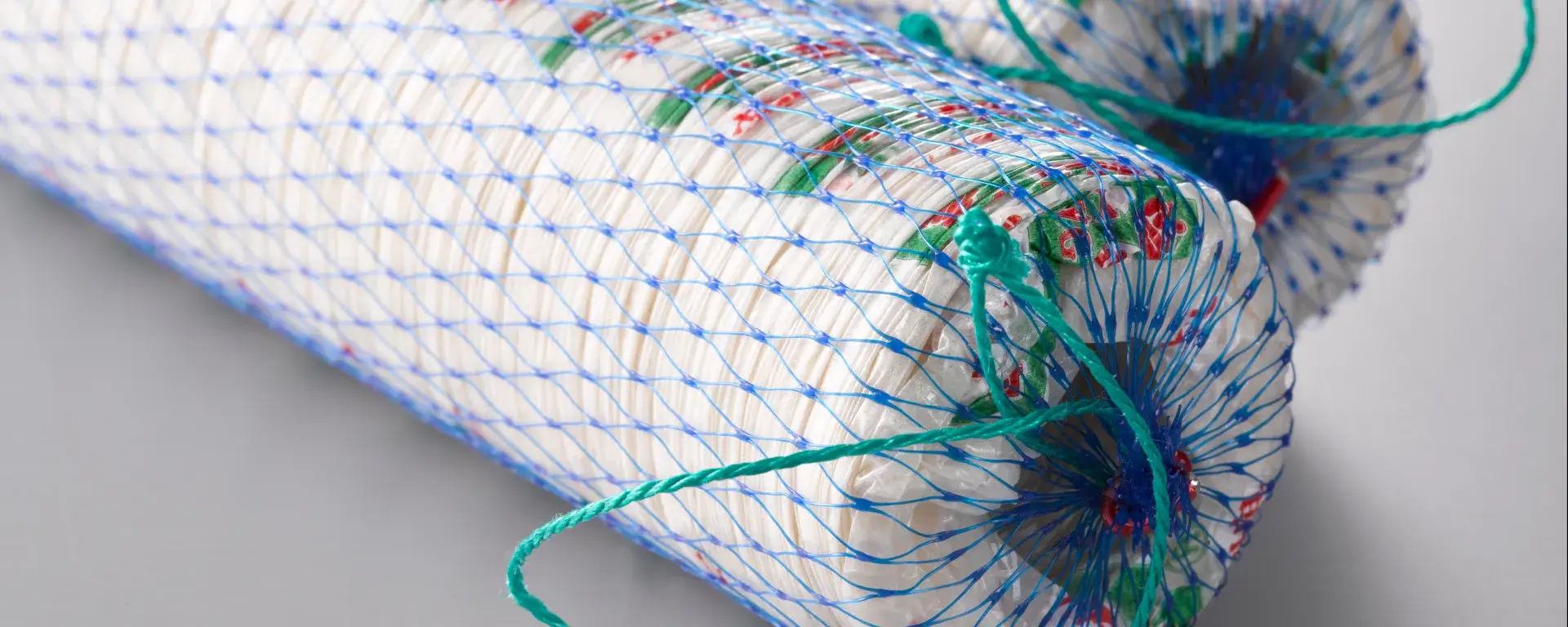

ViskoTeepak is focusing on very high standards when it comes to fibrous shirring. To achieve these standards, we rely on the latest technology, something we have developed ourselves. Several years ago, ViskoTeepak made the switch from paddle and screw shirring to spiral shirring with our own modifications. Thanks to these modifications, we have been able to use larger mandrels on certain occasions, resulting in a larger inside diameter, more meters on a strand, and increased flexibility in using highly moisturized treatments. All these modifications can help our customers produce higher quality products or increase capacity without the need for additional stuffing machines or personnel.

New water-based printing inks

New water-based printing inks that are aziridine-free and compliant with all food contact regulations, ensuring optimal ink adhesion on all casings. Our proactive approach began in April 2019, when we initiated testing of aziridine-free inks with two suppliers. By mid-October 2022, initial results were unsatisfactory, necessitating further development. The ink development process for ViskoTeepak fibrous casing presented unforeseen challenges for both suppliers. Achieving optimal ink adhesion on all casings within a tight time frame proved particularly daunting. Despite extensive testing, practical limitations hindered one supplier’s ability to achieve desired results.