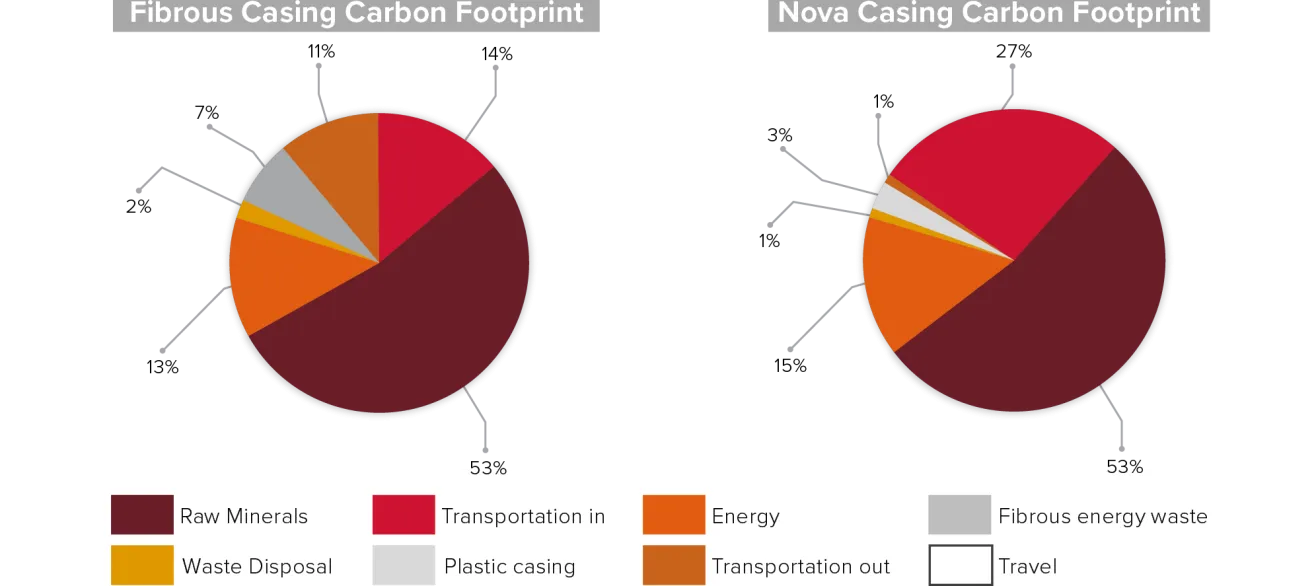

Carbon footprint was calculated using the principles set forth in the SFS-EN ISO 14067 standard. The calculation was made for casing manufactured in 2021. In the calculation, all the significant carbon dioxide sources were considered from raw materials to product disposal. The calculation was made using the principles of LCA (Life Cycle Assessment), and all carbon dioxide sources were taken into account including raw materials, transportation of raw materials, energy used in production, waste disposal in production, transportation of the casing to the

customer and disposal of casing after use.

As a result, the carbon footprint for fibrous casing was approximately 100 kg CO2 equivalent per kilometer of produced casing. The same result for plastic casing was 290 kg CO2 equivalent per kilometer of produced casing. The difference between the results can be explained by different raw materials used in manufacturing process. A part of it can also be attributed to the energy consumption in each manufacturing process.

After reading this, you may be thinking, but what is a carbon footprint? A carbon footprint is the total amount of greenhouse gases (including carbon dioxide and methane) that are generated by our activities. The optimal carbon footprint ranges from 6,000 to 16,000 pounds of greenhouse gasses per year per person. The typical low carbon footprint is between 16,000 and 22,000 pounds. In the Sustainability Report released this year, we discuss the constant changes we continuously implement to improve our carbon footprint. For example, the Hanko plant has been using wood residues as the major energy source for heat generation since 2013. Since it is considered to be a renewable-resource, our carbon-dioxide footprint for heating energy generation is consequently 0 tons of CO2. This is just one of the many changes that we have accomplished throughout the years. To read more about achievements and initiatives at the other ViskoTeepak locations, check out our 2023 Sustainability Report at www.viskoteepak.com.